Rotate your tablet

for a better experience

Rotate your tablet

for a better experience

At ArianeGroup, digitization and automation are crucial to ensure continuous improvement of operational efficiency.

A great example can be seen in action at our Ottobrunn site.

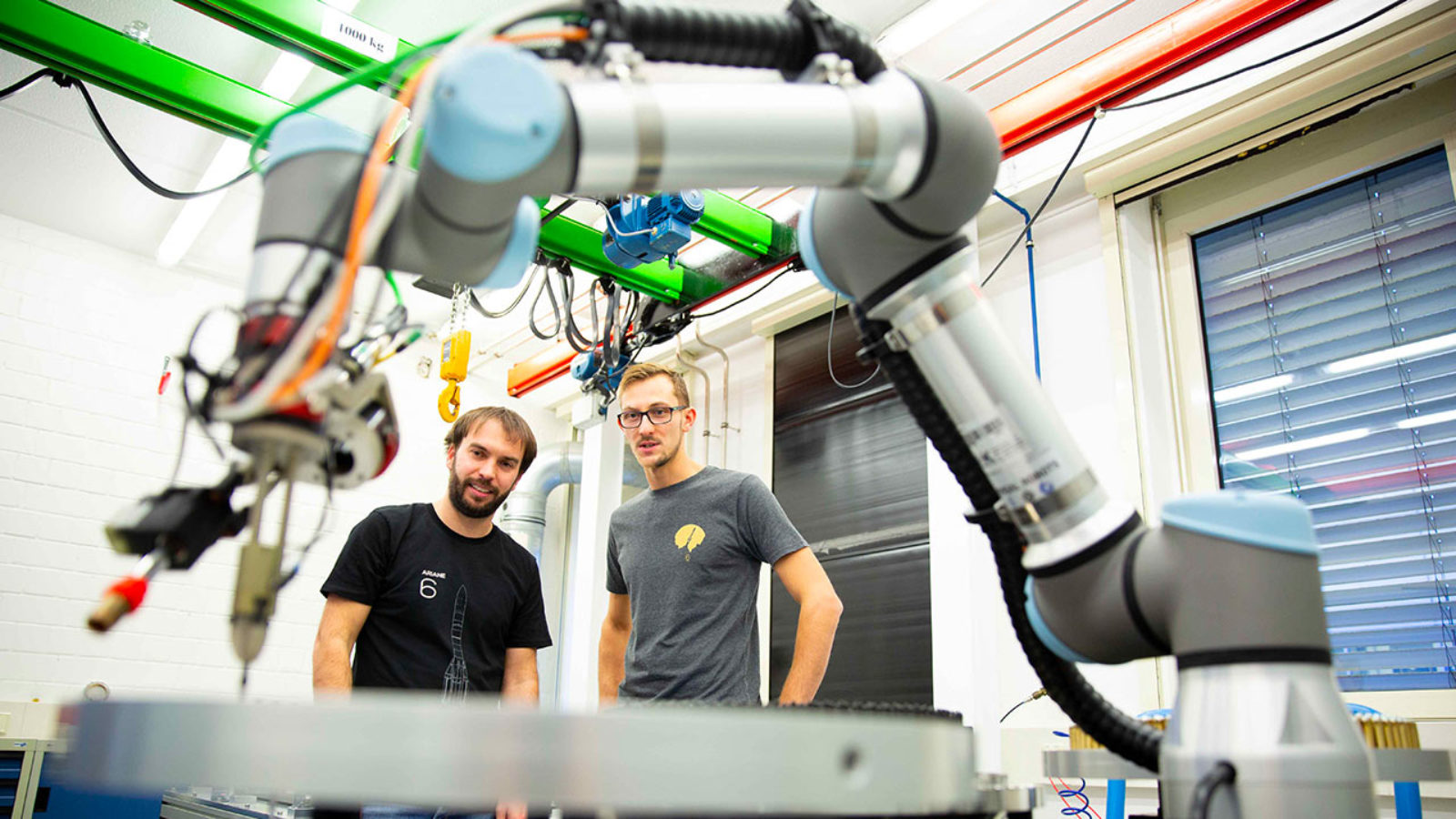

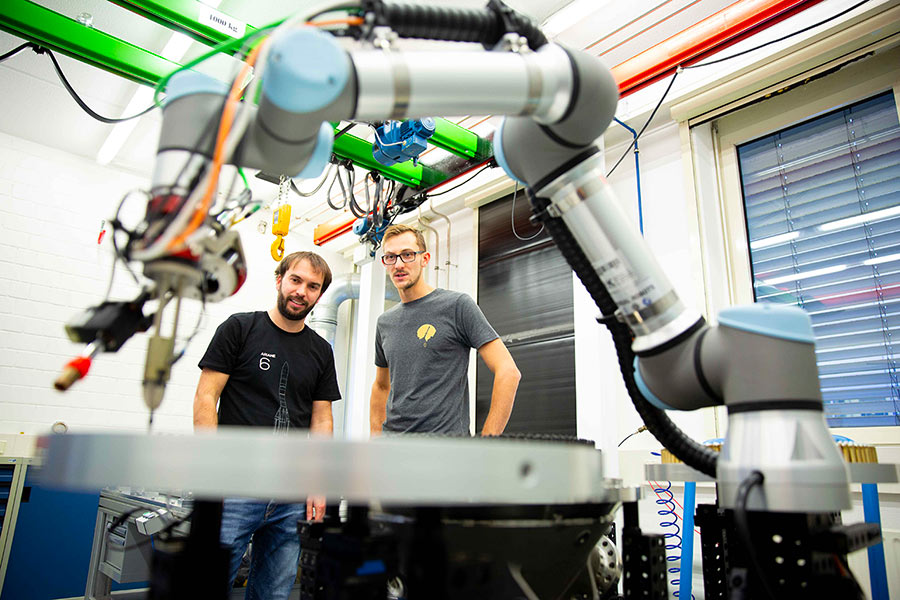

At the ArianeGroup site in Ottobrunn, Germany, the Industrial Test team use collaborative robots, cobots for short, to perform fast, precise quality testing.

An essential part of the team’s job is to conduct extensive tests for fuel flow rate, leakage, and thermal resistance of combustion chambers and valves manufactured at their site.

“It all comes down to this: we only get one shot for each rocket launch. That means that our team bears a huge responsibility to meet the highest quality standards,” explains department head André Kiessling. “Our job requires great precision and expertise. That is the reason why we have not been able until now to reliably hand over tasks to automated means.”

But now the team has found the solution: cobot installations that include a self-constructed platform and in-house 3D-printed material with the robots directly programmed and equipped by team members to meet the specific requirements of combustion chamber tests.

According to Team Manager Marius Schütterle, creativity and acumen always pay off: “For example, one of the tests for the Vulcain 2 combustion chamber consisted of sealing nearly 600 injector parts with plastic plugs, screwing on brass connectors, and then undoing the whole thing once the test was over. We have been doing things by hand for ages, and for hours on end. The cobots handle it now, which means I can organize my work days in an entirely different manner, and oversee several tests simultaneously.”

Two cobots are now part of the testing center at Ottobrunn; one of them is currently undergoing qualification. In addition to running the Pick-and-Place application (affectionately nicknamed Picky), which is used to prepare injection heads, the robots also test the flow rate of cooling lines in the combustion chambers.

“We try to make the installations better each time”, adds André. For example, the use of cameras is being considered to improve alignment, and record testing procedures.

The use of cobots has spurred constructive competition between users of the new technology. “We are part of a fast-growing community within ArianeGroup. There are now several departments on different sites that are currently working with cobots and we all share our experience, best practices and advice.”

In this video, the team gives a detailed explanation of how the cobots are used.

© Universal Robots