Rotate your tablet

for a better experience

Rotate your tablet

for a better experience

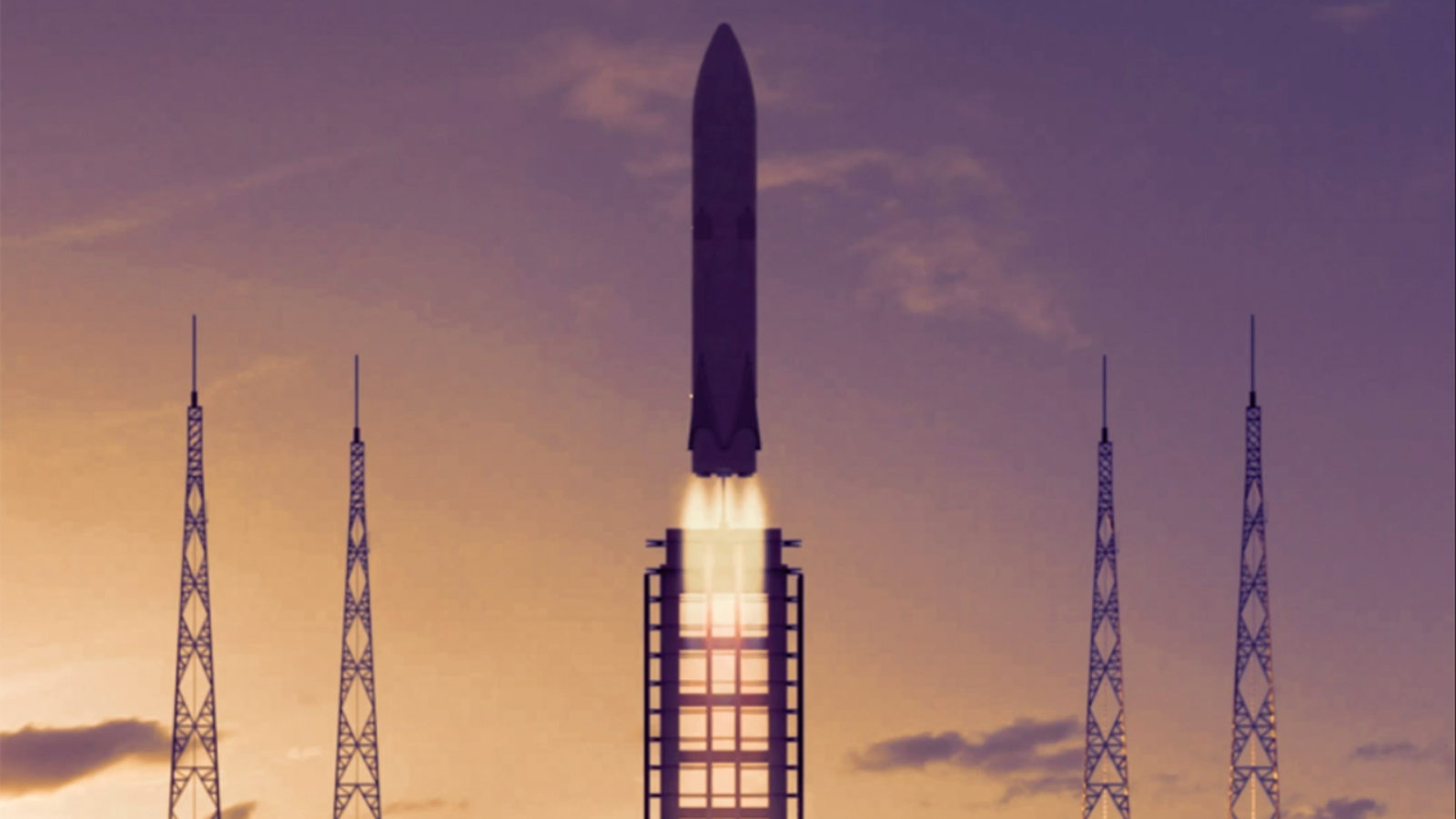

The latest on the development of the Themis demonstrator by ArianeWorks, the acceleration platform being run in collaboration between ArianeGroup and French space agency CNES

©ArianeWorks

After an earlier article highlighting the projects to refurbish the Diamant launch pad for Themis (the upper stage demonstrator for a future reusable launcher), many of you wanted more details about this ongoing project. From Themis 1 to Themis 3, the design and production roadmap for the demonstrator is dense.

We are currently working on this site on a ground test bed. This means that ArianeWorks is implementing a range of items necessary for operation of the engine, including the two cryogenic propellant tanks fueling the engine, equipped with their filling and drain lines and a pressurization system.

This step is designed to test filling, drainage and correct pressurization to ignite the Prometheus® engine, the new ArianeGroup engine demonstrator. These tests will enable ArianeWorks to test the use of new propellants, that is the LOx/CH4 (liquid oxygen and methane) combination, in the right conditions for fueling this engine.

For this second step, we are building a stage which will have geometrical characteristics and use materials closer to those of an operational stage (in terms of choice of technologies, materials, processes), with the Prometheus® engine, but with just a limited number of equipment items. This is because the main aim here is to validate the ground operations and then ignite the Prometheus® engine for the first time.

During this step, another stage will be designed and built, again with a Prometheus® engine. This time, it will be a real first stage, but once again with just enough equipment to achieve vehicle lift-off and recovery, and to advance project maturity in terms of reutilization.

We will carry out what are known as “hop tests”, lift-off to a low altitude of a few tens of meters before landing again. This step will be extremely harsh on the launch pad, because it will not have time to cool down between lift-off and landing.

This step will repeat step 1, but this time the stage will be equipped with three Prometheus® engines in order to test the entire flight envelope: climb, flip, descent and engines-first vertical landing (called toss-back), requiring numerous attitude and speed management maneuvers.

We will very soon know more about all these steps and next time we meet we will be looking at how the demonstrator launch pad materials are selected. A really concrete issue!

ArianeGroup wishes to thank Marie Jacquesson, head of the Thermal Structure and Materials department of the CNES Launchers Division, for her time.